News

by inopor

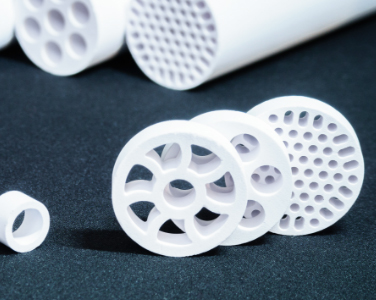

Inopor® Filtration-

membranes.

Leading in ceramic

nanofiltration.

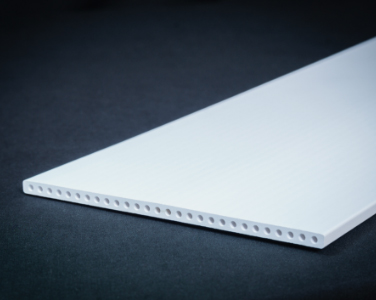

inopor® manufactures and supplies ceramic micro-, ultra-, and nanofiltration membranes in a wide variety of materials, geometries, and separation ranges.

inopor® offers market leading ceramic nanofiltration membranes with the smallest industrially available molecular cut-off. Ceramic nanofiltration membranes with a molecular weight cut-off between 200 and 750 Da are part of the inopor® standard product range.

In addition to the treatment of specific waste and process waters, these membranes are primarily used in the food, chemical, and pharmaceutical industries, as well as in biotechnology.

The separation mechanism of ceramic membranes is based on physical effects, which means that no additives are required during filtration operation. inopor® membranes are characterised by their high chemical and thermal resistance, which directly translates into a long service life of the filter elements.

In addition to manufacturing ceramic membranes, inopor® also specialises in the customised development of membrane separation processes in the fields of micro-, ultra-, and nanofiltration. An application centre equipped with its own laboratory and pilot systems is available for this purpose. This can also be deployed on-site at our customers’ facilities.

If required, we are pleased to offer our laboratory filtration unit “InoMini” for purchase.

We are happy to support you — in cooperation with our partners — in the development and acquisition of specialised pilot and industrial systems for filtration applications.

inopor® is certified according to DIN EN ISO 9001:2015.

![[Translate to English:] inopor – Industrie im Fokus: Milch](/fileadmin/user_upload/inopor/industrien/inopor-industrie-milch.jpg)

![[Translate to English:] inopor – Industrie im Fokus: Bier & Wein](/fileadmin/user_upload/inopor/industrien/inopor-industrie-abwasser.jpg)

![[Translate to English:] NanoKom - Team NanoKom project – using technical ceramics and industrial ceramics as stable supports for innovative separation processes](/fileadmin/_processed_/3/7/csm_rauschert-tec-news-MANTRA-Gruppenbild1__1__3bfcc1f585.png)