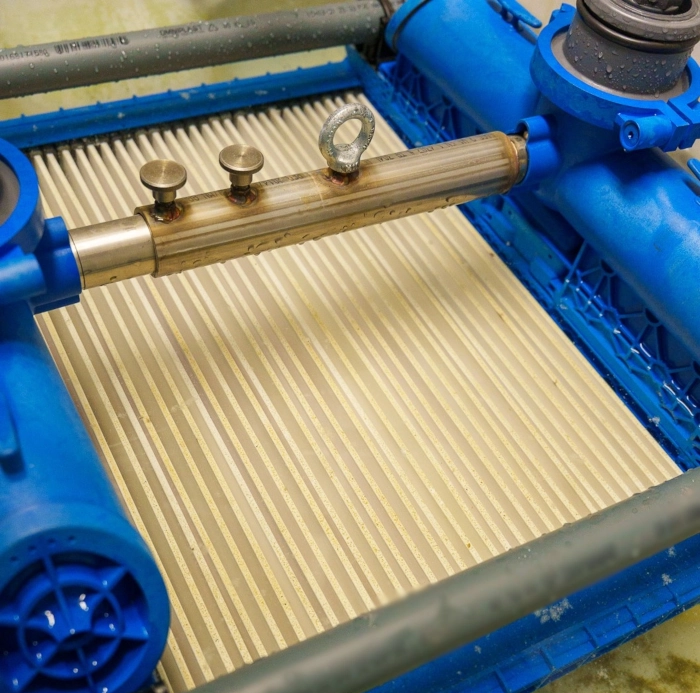

Inopor® multi-channel plates are ceramic plates made of high-purity aluminum oxide with a filter-active coating on the outside of the ceramic carrier. The filtration direction is therefore from “outside to inside.” For example, 34 multi-channel plates can be combined in one module. These modules can be used individually or in multiples as a filtration tower composed of modules.

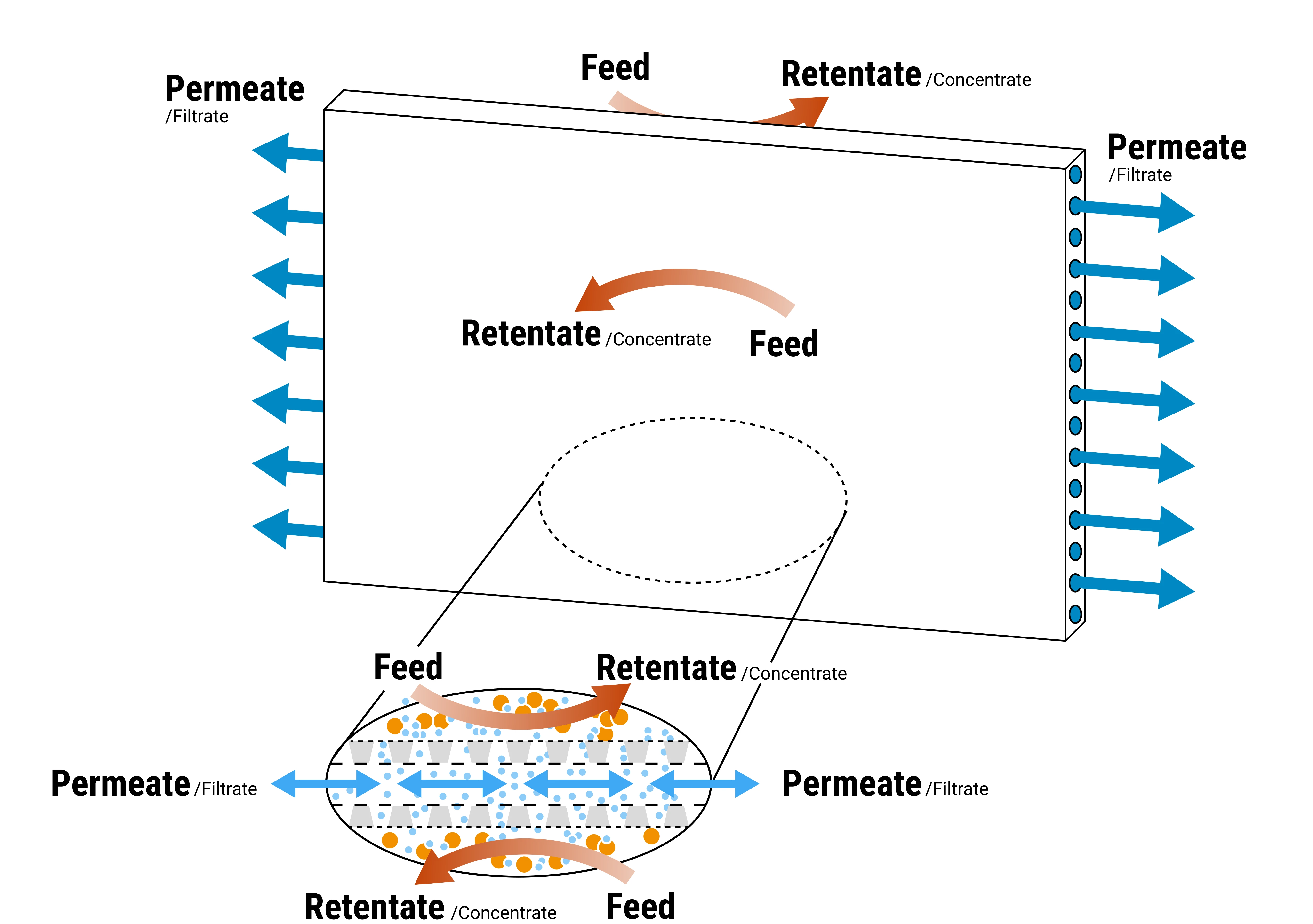

The modules are completely immersed in tanks into which the raw water is fed. Channels in the modules direct the permeate to a collection pipe, from where it can be used for further processing. The filtration method differs from cross-flow filtration and rotation disc filtration. In multi-channel plates, the filtration effect is achieved via the static pressure difference between the feed and permeate sides by means of negative pressure in the permeate channels. Due to the low pressure difference, a non-compressed filter layer forms, which leads to thicker filter layers. These can be detached from the multi-channel plate and removed from the inside to the outside by means of regular backwashing cycles.

This enables long operating times and short, uncomplicated backwashing phases with stable filtration results. The continuous removal of the permeate streams is ensured by a pump system. The result is a simple system design and high energy efficiency.

Download

In the download area, we provide you with various product information and application examples.