Advantages of Inopor® Membranes

- Separation limits down to the nanometer range

- High permeate flow

- Also suitable for highly viscous liquids

- Good chemical resistance,

- Acid and alkali resistant

- Resistant to organic solvents

- Finely tuned micro and ultrafiltration layers

- Rotary discs for laboratory and industrial applications

- Low cost of support, maintenance, and servicing

- Can also be used at high temperatures

- Backwashable

- Inert and tasteless

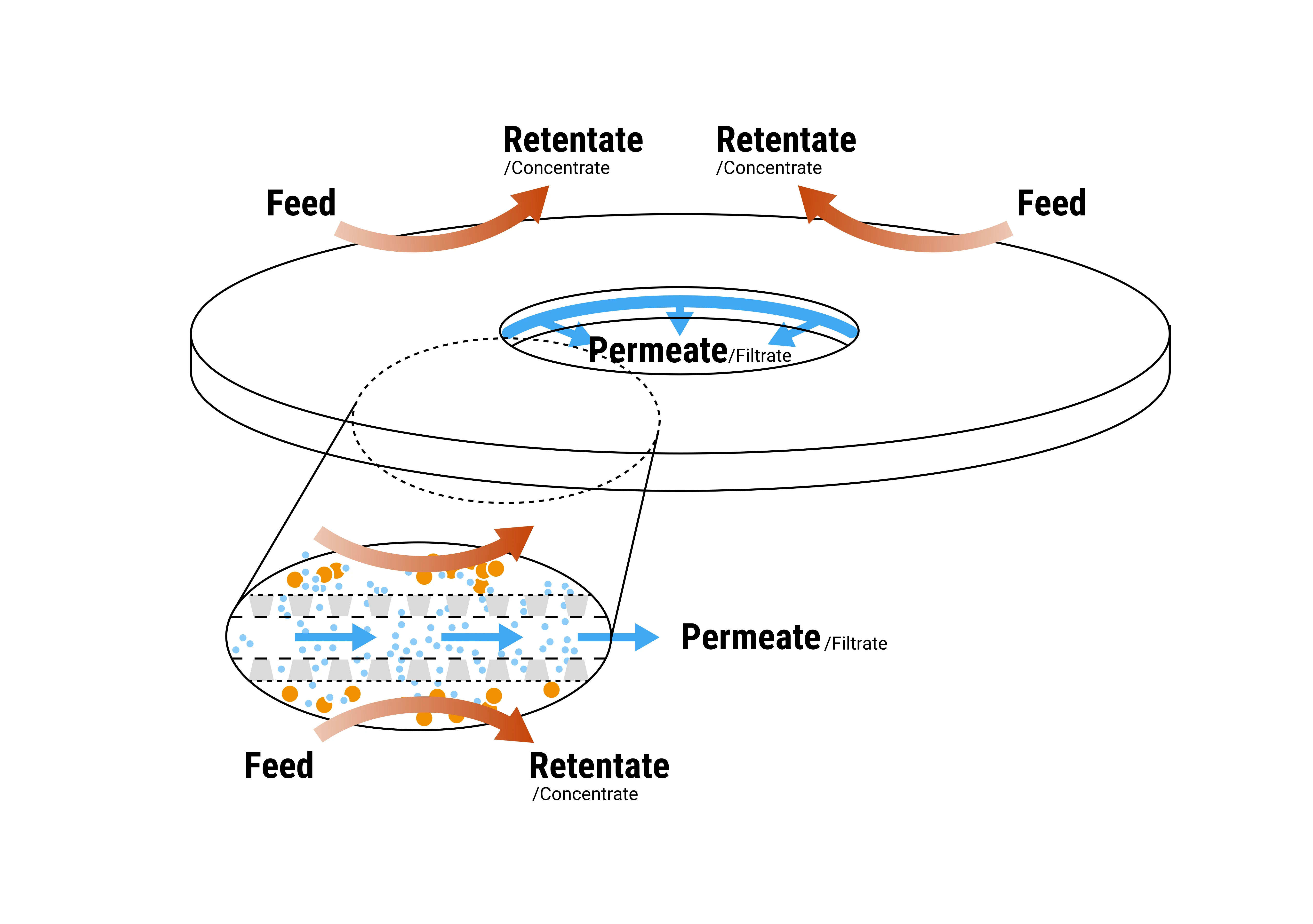

These discs are used in dynamic cross-flow filtration. The rotation of the discs causes tangential flow across the filter surface. This eliminates the need to pump large volumes of liquid, meaning that systems can be implemented with just one pump, which can significantly reduce energy costs depending on the application. The rotation enables extreme flow velocities, which can result in a highly efficient cleaning effect on the filter surface by regulating the surface layer and preventing fouling. This principle enables the filtration and concentration of highly viscous and highly loaded media.

Filtration principle

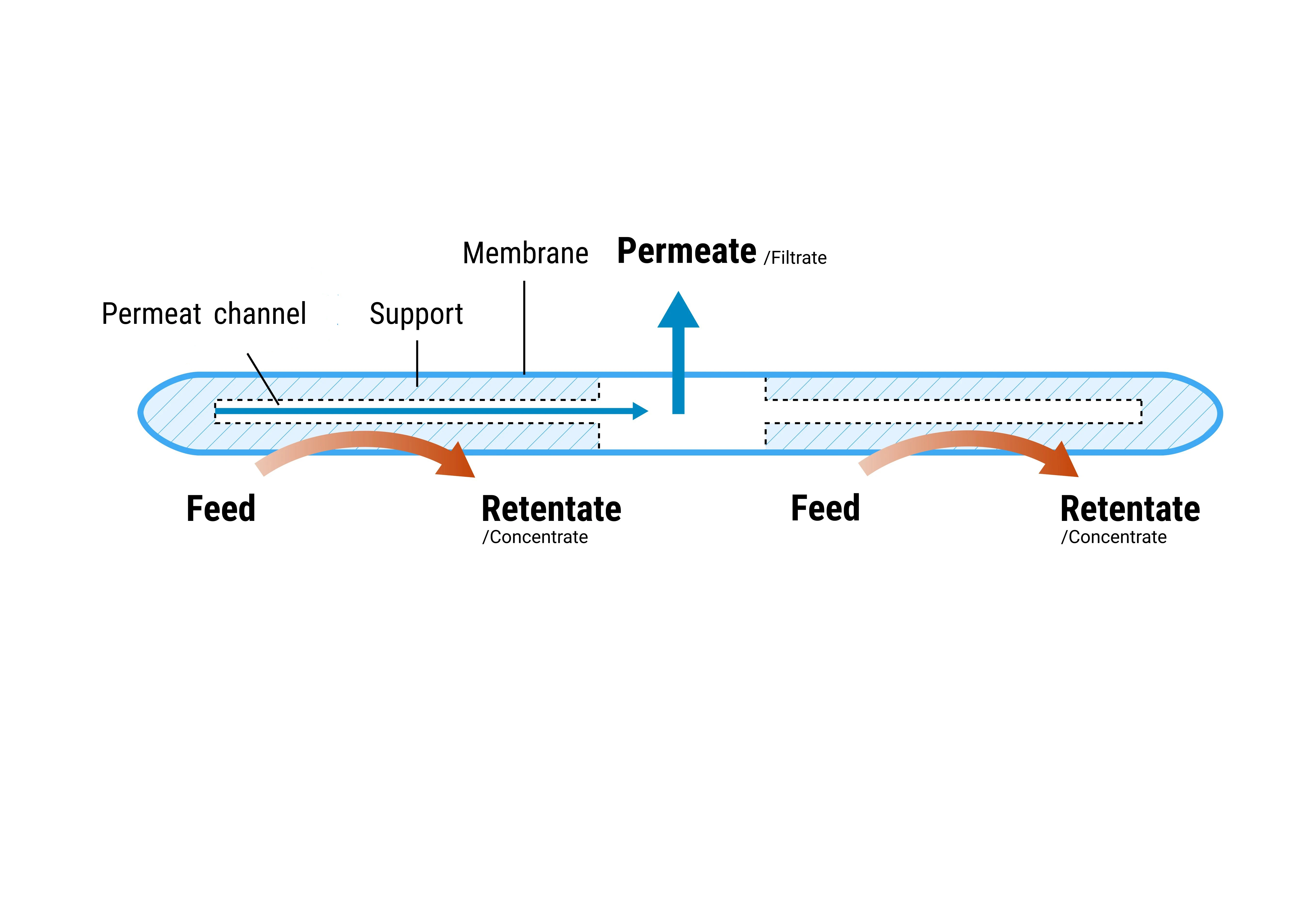

from “outside to inside”

At inopor®, we offer rotary discs in various geometries (sizes) and membrane pore sizes. The separation-active membrane is located on the outside of a disc, meaning that filtration takes place from the outside in. We and our partners are happy to assist with the design of systems.

The rotation of the filter discs creates the cross-flow effect and regulates the top layer.

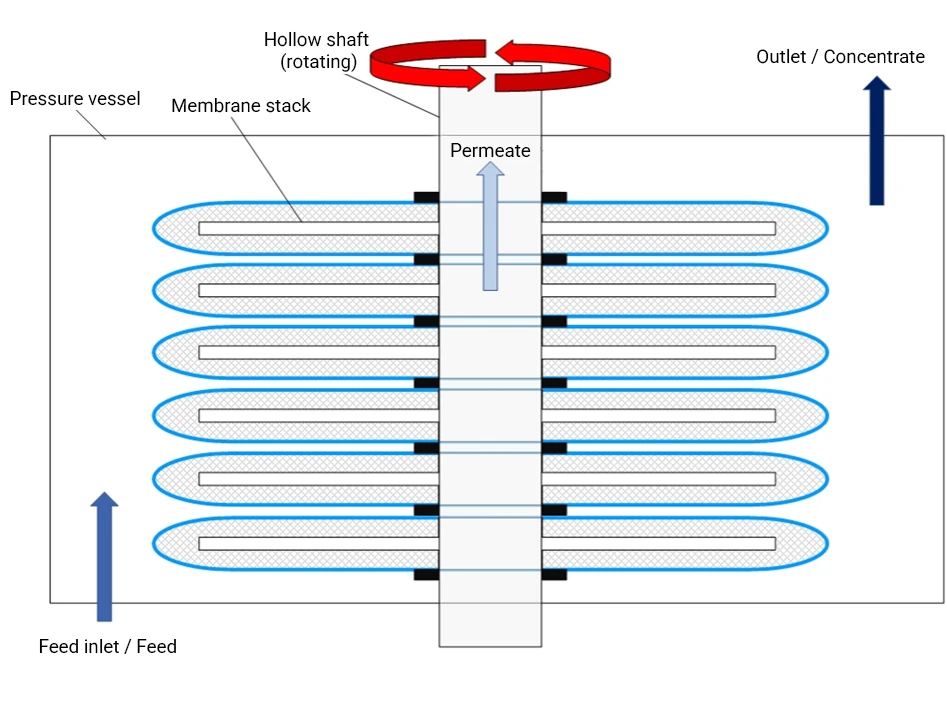

We assemble the rotating discs individually or in larger quantities as a stack in a pressure housing, which is filled with the medium/feed to be filtered. By setting an application-specific pressure, a uniform transmembrane pressure (TMP) can be achieved across the entire filter surface. With the TMP as the decisive driving force, the feed is filtered through the membrane of the rotating disc during the filtration process. Particles larger than the pores of the membrane are retained and concentrated during the process (concentrate). Particles smaller than the pores of the membrane (permeate/filtrate) pass through the support body to a hollow shaft through which the filtrate is discharged.

The rotation of the filter discs creates the cross-flow effect and regulates the surface layer. This is what distinguishes the rotating discs from the tubular cross-flow elements.

At inopor®, we mainly use dynamic cross-flow filtration. By using rotating discs, the rotational movement of the discs causes parallel overflow of the membrane. This overflow on the feed side allows deposited particles from the surface layer to be returned to the core flow.

Available geometries

Overview

We offer our inopor® rotation discs in various geometries for applications ranging from laboratory to industrial scale. These differ in height as well as in inner and outer diameter, resulting in varying membrane surface areas.

Standard geometries are available upon request.

Pore sizes

in detail

The product range of our inopor® rotary discs includes membranes for microfiltration, ultrafiltration, and nanofiltration. We manufacture our membranes from different materials and with different pore sizes in the separation layers.

As the global leader in ceramic nanofiltration, Rauschert offers inopor®—technologically advanced products available on an industrial scale with a separation limit of up to 200 Da. In addition, depending on the requirement profile, we also offer inopor® special membranes, such as modified membranes (hydrophobic properties) or membranes for particularly abrasive media, high temperatures, and high/low pH values. These can be easily integrated into existing plant concepts.

Downloads

In the download area, we provide you with various product information and application examples.