Advantages of inopor® membranes

- Separation limits down to the nanometer range

- High permeate flow

- Good chemical resistance, acid and alkali resistant

- Resistant to organic solvents

- Finely tuned micro and ultrafiltration layers

- Tube geometries for laboratory to industrial applications - up to 1.20 m in length

- Low effort for support, maintenance, and servicing

- Usable at high temperatures

- Backwashable

- Inert and tasteless

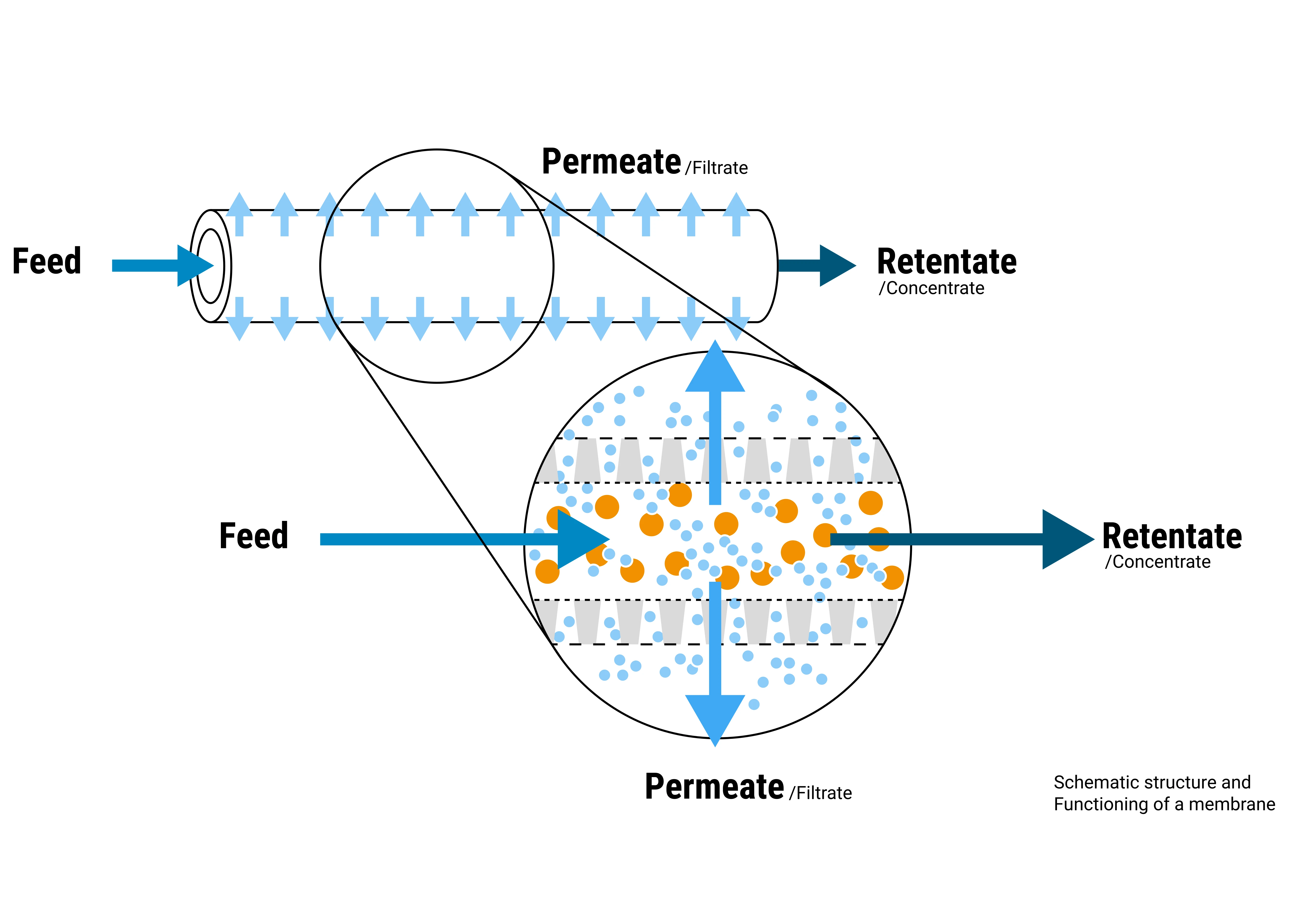

Filtration principle

Our inopor® membranes are semipermeable and therefore partially permeable separation surfaces. They are selectively permeable to at least one component of a fluid—gas or liquid.

In addition to the operating conditions, the retention of particles is fundamentally determined by the ratio between the size and structure of the particles and the size and structure of the membrane pores. On the membrane side, the pore size and pore size distribution determine the separation efficiency.

A particle/molecule can be retained if it is slightly larger than the pore diameter. When separating larger particles or undissolved molecules, a cover layer forms. In addition to the surface layer, this has an additional filtration effect. The driving force for the filtration of liquids is the pressure difference (TMP = transmembrane pressure) and for gases the partial pressure difference.

Technologies

in Focus

Microfiltration

Microfiltration is a pressure-driven process in the low-pressure range. In almost all applications where microfiltration membranes are used, a cover layer of larger particles forms. This cover layer is also desirable due to its additional filtration effect. This reduces the risk of internal blockage by smaller particles.

Microfiltration describes a physical separation process for suspensions and emulsions. Typically, particle or molecule sizes in the range of 0.1–10 micrometers (µm) [100–10,000 nm] are separated.

Ultrafiltration

Like microfiltration, ultrafiltration is a pressure-driven process. Ultrafiltration membranes are also porous membranes and operate in the medium pressure range. In most applications, they also form a cover layer. Due to the smaller pore sizes, it is possible to retain a larger number of smaller particles than with microfiltration membranes. Ultrafiltration can typically separate particles or molecules in the range of 0.01–0.1 micrometers (µm) [10–100 nm].

Nanofiltration

Ceramic nanofiltration membranes also have a porous structure. Ceramic nanofiltration membranes operate in a higher pressure range and separate particles and molecules in the range of 1–10 nanometers (nm). This type of filtration already makes it possible to filter multivalent ions (e.g., salt ions) out of the feed stream. Nanofiltration membranes with a pore size of less than 1 nm achieve a separation limit based on a molecule size of 450 daltons [450 g/mol]. Our products include ceramic membranes with a separation limit of approx. 450 Da and lower.

Due to the interaction of physical filtration with other effects, we recommend testing new applications in our inopor® application technology centre.

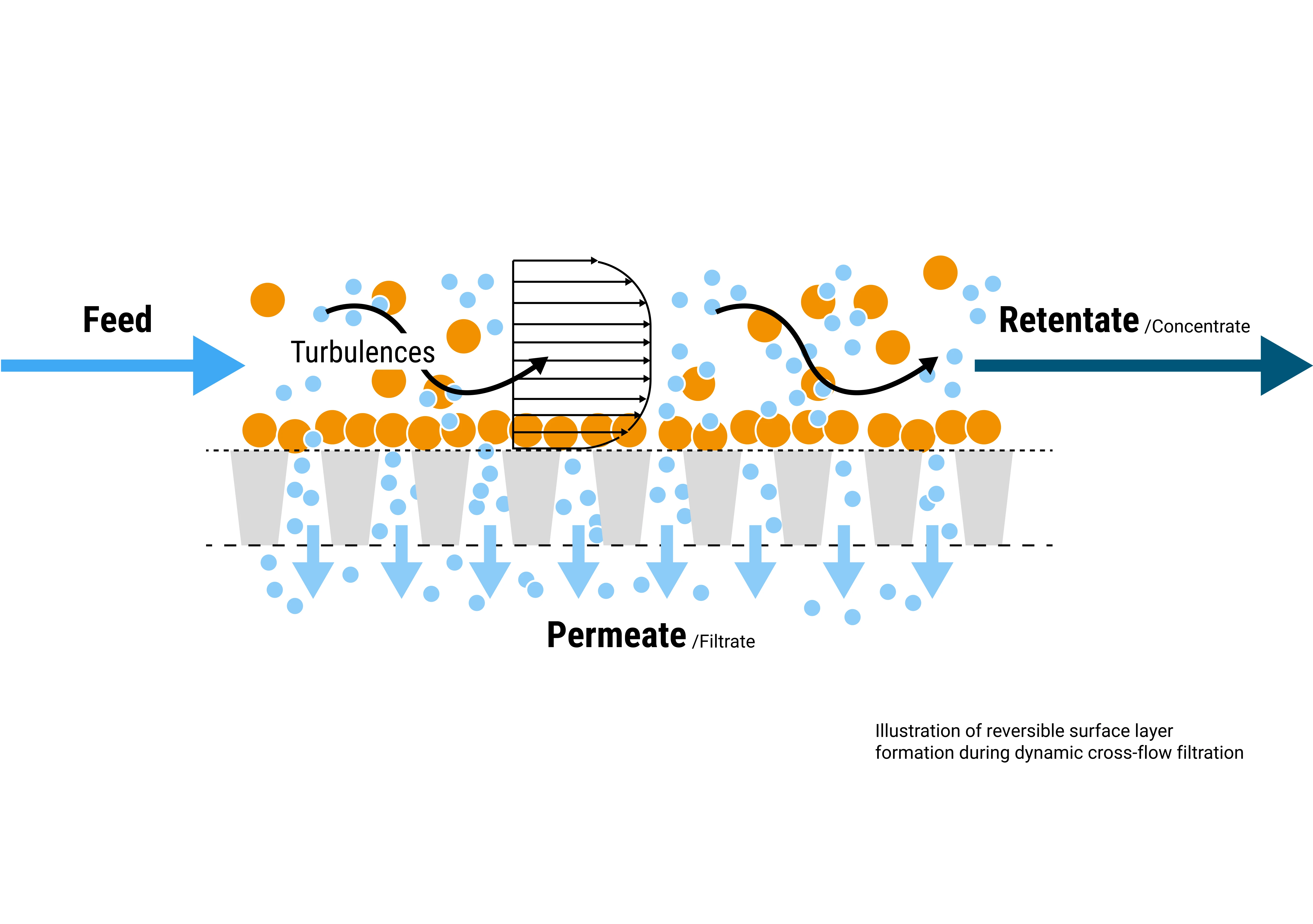

Formation of a surface layer in the filtration process

Filtration separates the process stream feed into retentate/concentrate and permeate/filtrate. The separation limit—particle or molecule size—is largely determined by the pore size of the membrane. During filtration, particles often accumulate on the surface of the membrane. These deposits form a coating that reduces the flow through the membrane and thus affects the efficiency of filtration. By adjusting the operating parameters of the filtration system – overflow and flow through the feed side – deposited particles can be returned from the cover layer to the core flow and removed as concentrate. This allows the formation of the surface layer to be controlled. This is also known as reversible surface layer formation.

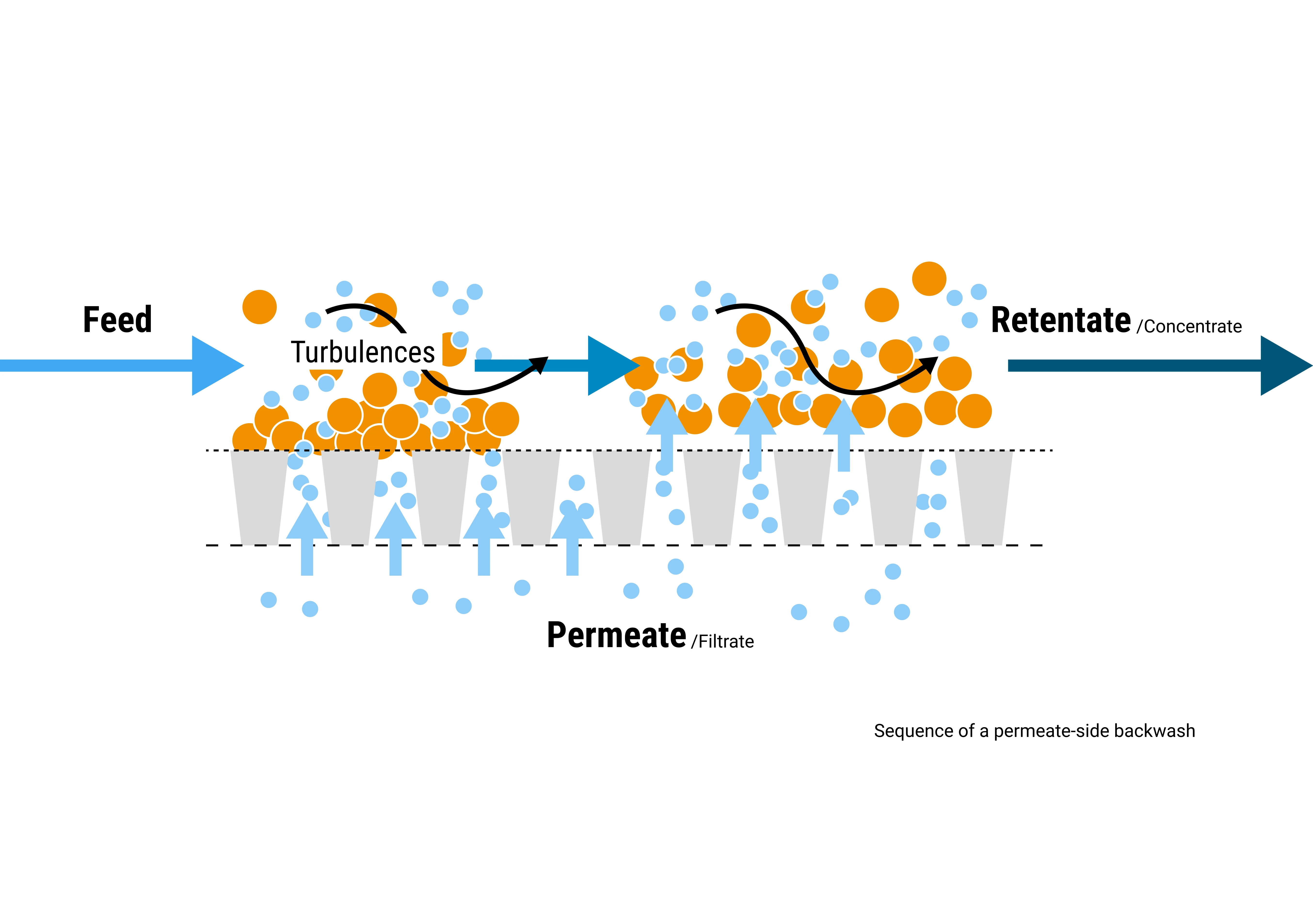

After a certain running-in phase, a steady permeate flow is established, enabling continuous operation of the filtration system. In addition, the top layer can be regularly removed by backwashing the membrane if necessary. Inopor® membranes are suitable for backwashing. Backwashing itself is controlled by the filtration technology, i.e., the operating mode of the filtration system.

If the layer that forms still blocks the flow, it can also be removed. Backwashing can be used to remove the surface layer. This works by briefly reversing the filtration process. Pressure is applied to the permeate side at high overflow. The surface layer lifts off the membrane and is carried away by the overflow. Continuous flow can be achieved by repeating the backwashing cycle.

From “feed” to “permeate”

The medium to be separated is called the “feed.” The feed stream flows through the flow channels/flow channel of the filtration element, which has a porous structure. The so-called ‘permeate’ or “filtrate” with the components that have passed through to the permeate side of the membrane element. The feed stream enriched with the retained components is thus concentrated. It is then referred to as the “retentate” (concentrate).

An important parameter of a membrane is its “permeability,” measured in l/(m²∙h∙bar). It indicates how many liters of permeate are produced per hour per square meter of membrane surface area at a pressure difference of one bar. Another value is the “retention” or “retention capacity.” Retention shows what percentage of a substance component is retained by the membrane.

Membranes & pore sizes

Details

The product range of our inopor® filtration tubes includes micro-, ultra- and nanofiltration membranes. The membranes are made of different materials. They also differ in the pore sizes of the separation layers.

As the world's leading brand in ceramic nanofiltration, we at inopor® offer cutting-edge products on an industrial scale with a separation limit of up to 200 Da.

We also offer inopor® special membranes depending on the requirement profile. These include, for example, modified membranes (hydrophobic properties) or membranes for very demanding conditions such as abrasive media, high temperatures, and high/low pH values. These can be easily integrated into existing plant concepts.

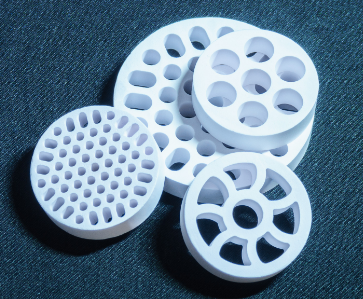

Membrane geometries

Overview

We sell individual membranes for microfiltration, ultrafiltration, and nanofiltration in various geometries. We offer test geometries with a length of 500 mm. Industrial geometries are available in standard lengths of 1178 mm and 1200 mm. Special lengths are also available on request.

A tabular overview of the different geometries can be found in our download area. Different geometries can be used depending on the type of application. This increases flexibility, allowing a wide range of applications to be exploited. We would be happy to advise you on the optimal geometry for your filtration process.

inopor® filtration tubes are sealed at both ends. Different materials are available for this purpose, depending on the application. You can choose between ceramic, glass, or Teflon seals.

All tubular membranes are designed according to a defined scheme. The design of each geometry type differs in terms of geometry, length, support, separating layer (membrane), and type of seal.

Certificates and declarations of conformity for membranes and modules are available on request.

Cross-flow-modules

The right foundation

We offer standard housings for various membrane geometries. The filtration housings assembled with membranes form the functional components of a filtration system. Depending on the design of the filtration process, different standard housings with different numbers of membranes can be installed in the filtration system.

We offer customised, tailor-made solutions for special requirements.

For special applications, such as in the food and pharmaceutical industries, we offer filtration elements and module designs in accordance with GMP guidelines and with minimal dead space volume.

Certificates and declarations of conformity for membranes and modules are available on request.

Downloads

Details

In the download area, we provide you with various product information and application examples.

![[Translate to English:] Inopor®-Membranen bieten flexible Geometrien für Mikro-, Ultra- und Nanofiltration mit hoher Filtrationsleistung](/fileadmin/_processed_/8/f/csm_inopor-cross-flow-filter-geometrien_batcheditor_fotor_6ea7d1213c.png)